| Payment Type: | L/C,T/T |

|---|---|

| Incoterm: | FOB,CFR,CIF |

| Min. Order: | 20 Set/Sets |

| Delivery Time: | 15-30 Days |

Basic Info

Model No.: 1815, 1820, 1825, 1830 heat pipe solar collector

Additional Info

Packaging: pre-assembled in cartons or packed seperately in cartons

Productivity: 2 million square meters of col

Brand: Linuo Ritter International

Transportation: Ocean

Place of Origin: China

Certificate: Solar Keymark, CE,ISO9001,ISO14001,OHSAS18001

HS Code: 84191910

Port: Qingdao

Product Description

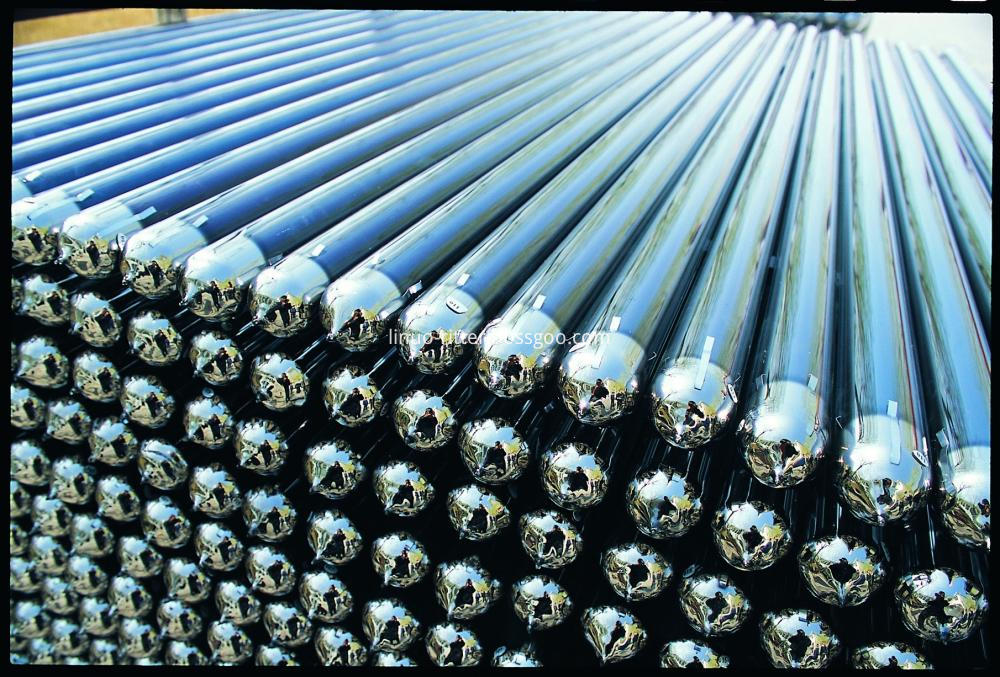

Heat Pipe Solar Collector Work Principle:

1. Solar absorption: solar radiation is absorbed by the evacuated tube and

converted into heat

2. Solar heat transfer: Heat pipes conduct the heat from vacuum tube inside to header

tank of solar collector.

3. Solar energy storage: water or other liquid is circulated through the header tank,

via intermittent pump cycling.

4. Circulation between solar collector and storage tank: each time the water or other liquid

circulates through the header tank, the temperature is raised by 5-10°C, the water in the

storage tank is heated gradually by this way.

Advantages and benefits

- Short installation times due to complete pre-assembled collectors.

- Manageable module sizes for a very high performance and a quick and easy

installation.

- Flow and return pipes may be filled on the left or the right side of the

manifold.

- High flexibility due to the different widths and lengths of the collectors.

- Pressurized and non-pressurized operation.

- Season independent operation depending on the heat transfer medium.

- Rapid thermal conductivity.

- High energy yield and low heat loss due to the high vacuum of the evacuated tubes.

- Operating at minimum ambient temperatures of -30 °C to maximum operating temperatures of 90 °C.

- Two loop system to constantly maintain a good water quality and to ensure water on cold days due to the anti-freezing medium in the solar circulation loop and an easy integration of other energy supplies.

High Efficiency Vacuum Tube Heat Pipe Solar Collector

1. European Solar Keymark certified heat pipe solar collector.

2. Brazil Inmetro certified heat pipe solar collector.

3. High efficiency of 74.5%.

4. High annual energy yield with 1808kwh each year for the 1820 heat pipe solar collector.

Key benefits:

- High collector efficiency of medium temperature suitable for pressurized and

non-pressurized solar thermal applications.

- Due to the rapid heat conductivity evacuated heat pipe collectors are

suitable for solar thermal applications in cooler areas with low ambient

temperatures.*

- Well-known indestructibility of the evacuated heat pipe collectors according

to DIN EN 12975-2.

| Series | R58-1812 | R58-1816 | R58-1818 | R58-1820 | R58-1824 | R58-1830 | ||

| Number of evacuated tubes |

|

12 | 16 | 18 | 20 | 24 | 30 | |

| η0 in relation to aperture, EN 12975 | % | 0.745 | 0.745 | 0.745 | 0.745 | 0.745 | 0.745 | |

| a1 with wind, in relation to aperture area | W/(m2k) | 1.875 | 1.875 | 1.875 | 1.875 | 1.875 | 1.875 | |

| a2 with wind, in relation to aperture area | W/(m2k2) | 0.007 | 0.007 | 0.007 | 0.007 | 0.007 | 0.007 | |

| Collector dimensions (LxHxD) | mm | 968x1910x110 | 1268x1910x110 | 1418x1910x110 | 1568x1910x110 | 1868x1910x110 | 2318x1910x110 | |

| Gross surface area | m2 | 1.848 | 2.421 | 2.708 | 2.994 | 3.567 | 4.427 | |

| Aperture area | m2 | 1.218 | 1.619 | 1.821 | 2.024 | 2.429 | 3.036 | |

| Collector contents | l | 0.638 | 0.854 | 0.961 | 1.069 | 1.285 | 1.608 | |

| Weight | kg | 40 | 53 | 58 | 67 | 81 | 99 | |

| Max. working overpressure | bar | 8 | 8 | 8 | 8 | 8 | 8 | |

| Max. stagnation temperature | °C | 245 | 245 | 245 | 245 | 245 | 245 | |

| Connection fitting diameter | φ (mm) | 22 | 22 | 22 | 22 | 22 | 22 | |

| Collector material |

|

Al / Cu / glass / silicone / PBT / EPDM / TE | ||||||

| Glass tube material |

|

Borosilicate glass 3.3 | ||||||

| Selective absorber coating material |

|

Cu / SS-AIN / AIN | ||||||

| Glass tube (Ø ext./ int./wall thickn./tube lgth.) |

|

58/47/1.6/1800 | ||||||

| Colour (aluminium frame profile, anodised) |

|

Aluminum grey | ||||||

| Colour (plastic parts) |

|

black | ||||||

| Heat Pipe | Working medium |

|

Super Conductivity Technology - Inorganic Media | |||||

| Operating pressure | bar | 0.8 | ||||||

| Startup temperature | °C | ≤30℃ | ||||||

| Copper type |

|

TP2 | ||||||

| Evaporation part diameter | mm | 8 | ||||||

| Thinkness of copper tube | mm | 0.6 | ||||||

| Evaporation part length | mm | 1700 | ||||||

| Condensation part diameter | mm | 14 / 24 | ||||||

| Thinkness of copper tube | mm | 0.6 | ||||||

| Condensation part length | mm | 55 | ||||||

| Thermal shock test / ITW test number |

|

154150039_Linuo_R1830-58-75_ISO_Report_chen | ||||||

| DIN CERTCO registration number |

|

011-7S2830 R | ||||||

| Package dimensions (LxHxD) | mm | 1060x1960x150 | 1360x1960x150 | 1510x1960x150 | 1660x1960x150 | 1960x1960x150 | 2600x140x120 | |

Contact Person: Guo

Phone:86-531-88729112

Fax:86-531-88729223

Address: No. 30766 East Jingshi Road,Jinan,Shandong

Sweep wechat

© 2019 CHINA WAY. All Rights Reserved. Linuo Ritter International Co.,Ltd, Inc. All rights reserved. site map. sitemap.html